top of page

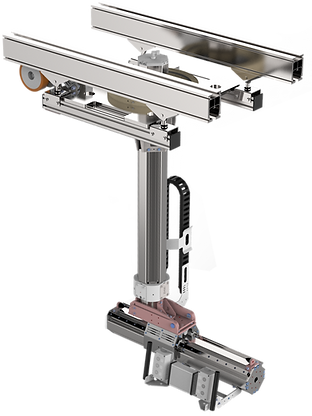

Lifting-Axis ZH90

The new ZH90 lifting axis is a reliable partner with its versatile expansion options. Wherever heavy loads have to be lifted, moved and moved, the ZH90 lifting axis makes work easier. It saves valuable time, promotes efficiency and the precise execution of activities. It protects people and their health.

With the ZH90 lifting axis, you can transport, move and lift objects with different weights and properties seemingly weightlessly and with little effort.

As a modular system, the ZH90 lifting axis can be used in almost every area and at every workplace

|  |  |

|---|---|---|

|  |

Technical data

Leistungsmerkmal / Feature | Einheit / Unit |

|---|---|

Gerätkürzel / Name | ZH90 |

Arbeitshub / Working Hub | max. 1.600 mm |

Tragfähigkeit / Load Capacity | 1.000 kg |

Antrieb / Drive | pneumatic / electropneumatic / electric |

Drehachse (Auslegearm) / Rotary axis (extension arm) | 330 ° |

Drehachse (Hauptachse) / Rotary axis (main axis) | 360 ° endlos / endless |

Drehachse (Vorrichtung) / Rotary axis (fixture) | 360 ° endlos / endless |

Momentbelastung / triggering torque | steif / stiff |

Torsion um Z-Achse / Torsion around Z-axis | 3.000 Nm (Hub 1.000 mm) |

Betriebsdruck / Operating pressure | 6 bar |

Geräuschentwicklung / Noise emission | < 70 db (A) |

Stromversorgung / Power supply | 230 V |

Eigengewicht / Net weight | 70 kg |

Schienensystem / Rail System | passend für jede Art von System / any system |

ZH90 lifting axis in use

bottom of page