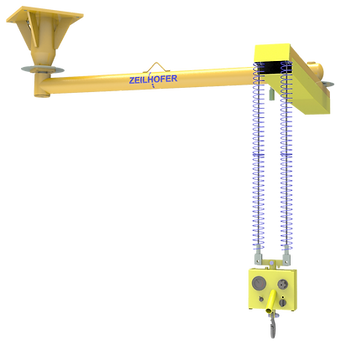

Rope articulated arm manipulator

Articulated arm manipulators from Zeilhofer Handling Technology are lifting aids that can be used both stationary and movably on the floor or ceiling. With their high flexibility and large working radius, they are the optimal solution to take the weight off the load and thus make work easier.

Each articulated arm lifting aid can also be equipped with an individual device as required. Zeilhofer Handling Technology offers you a complete product, from planning to aftersales.

Articulated arm manipulator

Articulated arm manipulators from Zeilhofer Handling Technology are lifting aids that can be used both stationary and movably on the floor or ceiling. With their high flexibility and large working radius, they are the optimal solution to take the weight off the load and thus make work easier.

Each articulated arm lifting aid can also be equipped with an individual device as required. Zeilhofer Handling Technology offers you a complete product, from planning to aftersales.

Articulated arm manipulator

Articulated arm manipulators from Zeilhofer Handling Technology are lifting aids that can be used both stationary and movably on the floor or ceiling. With their high flexibility and large working radius, they are the optimal solution to take the weight off the load and thus make work easier.

Each articulated arm lifting aid can also be equipped with an individual device as required. Zeilhofer Handling Technology offers you a complete product, from planning to aftersales.

Articulated arm manipulator

Articulated arm manipulators from Zeilhofer Handling Technology are lifting aids that can be used both stationary and movably on the floor or ceiling. With their high flexibility and large working radius, they are the optimal solution to take the weight off the load and thus make work easier.

Each articulated arm lifting aid can also be equipped with an individual device as required. Zeilhofer Handling Technology offers you a complete product, from planning to aftersales.

Technical data

Convincing values of the rope articulated arm manipulator:

Leistungsmerkmal / Features | Einheit / Unit |

|---|---|

Max. pneum. Tragfähigkeit / Load Capacity | 150 kg |

Max. Arbeitshub / Stroke | 2.000 mm |

Max. Arbeitsradius / Working Radius | 4.000 mm |

Drehachse (Hauptachse, Aufnahmevor.) / Rotary axis (main axis, receiving front) | 360° |

Drehachse (Auslegearm) / Rotation Axis (extension arm) | 330° |

Max. Betriebsdruck / Operating Pressure | 7 bar |

Geräuschentwicklung / Noise Emission | < 70 db(A) |

Rope articulated arm manipulator in use

Attached you will find application examples and videos for our rope articulated arm manipulators: